Partners

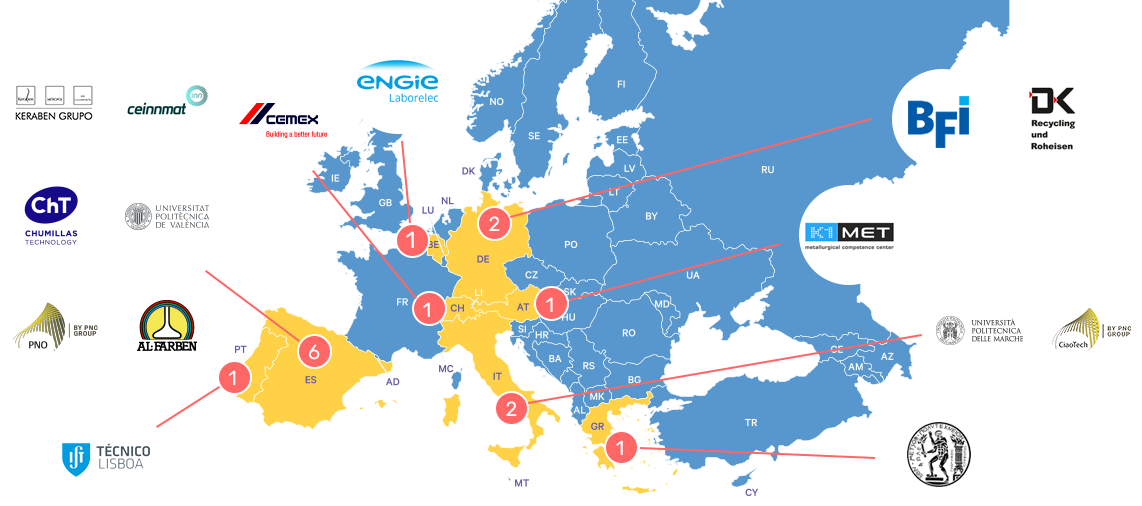

The DESTINY consortium is formed by 14 experienced partners with proved capability to develop and achieve the objectives of the project covering a wide geographical representation from 9 European countries of the best research organizations, technology & service provider, and industrial end users.

The multidisciplinary roles guarantee a deep knowledge and best available skills in the essential parts of the developments (materials development, microwave technology, environmental/cost/social life cycle analysis, health & safety, industrial processes for cement/ceramics/steel, business exploitation, etc).

KERABEN GRUPO S.A.

KERABEN is a Spanish company devoted to the manufacturing of ceramic tiles. KERABEN commenced its business activity in 1974 and since then, customer service and ongoing technological innovation have formed the basis of the company’s strategy. KERABEN enjoys a leading position in the sector of premium ceramic solutions delivering top quality products with a notable design component at the middle-to-high-end segment.

The finest raw materials, cutting-edge ceramic tile technology and the commitment to excellence shown by KERABEN’s professionals are the finest guarantees for the consistently outstanding quality of their products. Because of a firm commitment with the sustainability, KERABEN reuses 100% of the water from the production processes, apply cogeneration to make the most of the energy, reintegrates the waste products from each process into the ceramic tiles, works with 100% recycled packaging and have all the procedures certified.

INNCEINNMAT SL

CEINNMAT is a high-tech SME within the industry of materials processing providing and developing microwave and complementary emerging technologies. It is a private research-intensive company created in early 2010 in Castellon (Spain) with a research and equipment development delegation in Valencia University Science Park.

CEINNMAT develops microwave industrial technology for continuous flow material processing, fabricates and provides equipment-based microwaves and multi-source energy kilns for the industry, developing both the system and the equipment with proprietary technology.

NATIONAL TECHNICAL UNIVERSITY OF ATHENS - Laboratory of Heterogeneous Mixtures & Combustion Systems

NTUA.HMCS belongs to the Thermal Engineering Section of the School of Mechanical Engineering. It is an accredited laboratory established by Government Decree in 2002. It is served by 1 faculty member, 10 post-doc research associates, 5 doctoral candidates, approximately 15 graduate students on an annual basis and three members of staff for administrative and technical support.

NTUA.HMCS has participated in 35 EU funded projects since 2002. The main research areas of NTUA.HMCS include: Combustion thermochemistry, fundamental heterogeneous multi-phase, multi-component, reacting flows and related industrial processes; building materials and components under heating/cooling and fire conditions; fire growth in buildings coupled with energy saving and energy storage technologies; process optimization-energy auditing for buildings and industry; development of multi-criteria assessment tools integrated with Life Cycle Analysis for techno-economic & environmental impact assessment of energy systems and technologies.

UNIVERSITA POLITECNICA DELLE MARCHE - Department of Industrial Engineering and Mathematical Sciences

https://www.diism.univpm.it/?language=en

Università Politecnica delle Marche (UNIVPM) includes 5 Faculties: Engineering, Medicine and Surgery, Economy, Science and Agriculture. The organization is subdivided in 12 Departments for a total amount of 523 units among professors of I, II level and fixed-term researchers.

With reference to the activities to be performed during the project the research group in Mechanical and Thermal Measurement (MTM), belonging to the Department of Industrial Engineering and Mathematical Sciences (DIISM) within the Engineering Faculty, will be involved. The Group is at present composed of 5 professors, 1 lecturer, 10 research engineers, 16 PhD fellows and a variable number of young engineers with contracts. The members of the group are partly mechanical engineers, partly electronic engineers; this cross-sectorial range of competences is an element of strength for developing research in the transversal domain of measurement techniques.

UNIVERSITAT POLITECNICA DE VALENCIA - ITACE Research Institute (DIMAS)

https://itacadimas.wordpress.com/

The Universitat Politècnica de València (UPVLC) founded in 1971 is a dynamic, innovative and entrepreneurial public institution, devoted to training, research and technology transfer.

The Institute of Information and Communication Technologies (ITACA) is a research and development entity of the UPVLC, with a Microwave Division (DiMaS) with large experience undertaking scientific and applied research, technological development and technology transfer initiatives in the field of microwave engineering, such as electromagnetic characterization of materials at microwave frequencies, the design of the microwave systems to perform the required processing applications, and the manufacturing of laboratory-scale microwave prototypes to evaluate the different designs possibilities and optimizing the processing parameters in each case.

AL-FARBEN, S.A.

ALFARBEN as a member of the TORRECID GROUP operates within a multinational business group founded in 1963 and dedicated to providing products and services to sectors of ceramics, glass, coating and plastic.

ALFARBEN is located in the province of Castellón/Spain, occupying an area of over 75,000 m2, where it has a production center (with approximately 140 employees) equipped with all the proprietary technology as well as laboratory and pilot plant fully equipped for the development of R+D+ I in a short, medium and long term. ALFARBEN is fully focused on the world of inorganic pigments, which has allowed developing its own technology production creating facility of high volume production and a R&D centre to develop alternative synthesis routes for inorganic materials.

CHUMILLAS TECHNOLOGY, S.L.

http://www.chumillastechnology.com

CHUMILLAS offers customers comprehensive solutions for handling and processing of products in granular powder since 1981. Solutions are developed for engineering, manufacturing, installation, commissioning and after sales service facilities for the treatment of raw materials in various industries. Added value is generated according to customer needs thanks to the know-how acquired in a large professional experience.

The technical department carries out the equipment and process design according to actual regulations, adapts machines to keep CE certification and has the expertise for the development of tailored transport systems with the necessary equipment and instruments for the total control of all system parameters (weight, flow, pressure, speed, etc.)

VDEh-Betriebsforschungsinstitut GmbH

BFI with a staff of 100 people is a leading European provider of application focused R&D in the field of steelmaking technology. It is focused on the the steel industry executing top-level research and development, which meets the most exacting international standards.

BFI's field of activities covers the entire steelmaking process chain from charge materials to the final product. BFI’s core competences lie in the field of process development and engineering, energy and resource technology and measuring technology and process automation. BFI cooperates very closely with similar institutes all over Europe. BFI is deeply integrated in the national and international research networks. In 2014, 24 national and 57 international research proposals were applied for in a wide variety of research programs, e.g. RFCS, H2020, SPIRE.

K1-MET GmbH

K1-MET GmbH is a competence center for metallurgical and environmental process developments. Resource and CO2 efficient production of iron and steel as well as nonferrous metals are within the focus. Further activities are analysis, simulation and modelling of these processes and the integration of energy efficient concepts into existing production chains.

The used methods are based on a close cooperation between industries and scientific institutions with a mix of fundamental research, computer modelling, laboratory experiments and practical tests directly at the industrial facility. K1-MET has relevant experience in raw material characterization (dusts, slags and sludges) from blast furnace and converter process as well as from direct reduction ironmaking process and in the optimization of the sinter process regarding the influence of operating conditions on product quality and off-gas emissions.

DK RECYCLING UND ROHEISEN GMBH

https://www.dk-duisburg.de/index_en.html

DK is the world's largest recycler of ferrous waste materials in the steel industry. DK produces special pig iron from the supplied waste materials at a high profitability and sustainability level for the foundry industry in its facilities located in Duisburg Hochfeld.

DK relies on its more than 100 years old tradition and on its own developed and unique recycling process, the so-called DK-process. The process is based on the classical sintering and blast-furnace operations, and is a process that fully complies with the given recycling and waste legislation helping to recycle approx. 500,000 tons of ferrous waste materials at a resource's efficiency of 98% in a reliable and environmentally friendly manner.

CEMEX RESEARCH GROUP AG

https://www.cemex.com/locations/switzerland

Founded in 1906, CEMEX has a long experience in cement fabrication and is today one of the world’s largest traders of cement and clinker. CEMEX manufactures cement in more than 50 countries across four continents and has annual sales of more than US$15 billion.

The CEMEX Research Group AG (CEMEX) in Brügg by Biel, Switzerland, is a subsidiary of CEMEX S.A.B. de C.V., Monterrey, Mexico. CEMEX hosts and manages all R&D activities of all CEMEX entities. It is responsible for the development and innovation of technologies and products in the context of the CEMEX Group in all areas of product development, process technology, processes, IT and sustainability in energy and emissions.

CIAOTECH S.r.l. - PNO ES

CIAOTECH (as a wholly owned company and Italian branch of the PNO Group) and PNO ES represent Europe’s largest independent public funding and innovation consultancy with 30 years of hands-on expertise with more than 500 funding programmes in most EU countries, annually raising approximately 1 Billion Euro for its clients.

BELGISCH LABORATORIUM VAN DE ELEKTRICITEITSINDUSTRIE

LABORELEC is a leading research and competence centre in electrical power technology (240FTE, ~56M€). It was established in 1962 in Belgium in order to support Belgian electricity companies with research, development, and specialized services. Today, it is part of ENGIE, a world leader in energy. LABORELEC competences cover the entire electricity value chain: generation, transmission, distribution, storage and end-use.

LABORELEC competences cover the entire electricity value chain: generation, transmission, distribution, storage and end-use. LABORELEC offer specialized research and services in each of these domains, to companies in all parts of the world. More specifically for electrical equipment, LABORELEC offers a vast array of services to guarantee the reliability of electrical equipment on various levels. It includes on-site electromagnetic measurement and troubleshooting, electromagnetic compatibility simulations and electromagnetic compatibility quality. LABORELEC offering also include earthing advice for industrial electricity networks, feasibility studies for connecting wind turbines, heat pumps, and other decentralized generation units to nation-wide electricity grids etc. Through the research LABORELEC improves the operational excellence of existing electrical power assets, prepare the customers for their future challenges, develop new solutions for energy end-users needs, and anticipate and explore the potential and risk of emerging energy technologies.

INSTITUTO SUPERIOR TÉCNICO / UNIVERSIDADE DE LISBOA

https://tecnico.ulisboa.pt/en/

Instituto Superior Técnico (IST) is the largest school of engineering in Portugal with long tradition in teaching, excellence in research, innovation and training activities. With three conveniently located campuses, (Alameda in Lisbon, Taguspark in Oeiras) and Technologic and Nuclear in Loures), IST consists of 10 Departments and 1 Autonomous Section being responsible for teaching Undergraduate and Postgraduate Programs.

Today, IST has about 10,000 undergraduate students and over 1,500 graduate students in different areas of studies. The faculty of IST includes over 700 Professors with Ph.D. in different areas of specialization. The scientific activities are developed in research institutes, some of them of excellence, in which working groups develop research in specific subjects within its scientific area. The Mechanical Engineering Department has around 80 PhD holders that have participated in many FP6 and FP7 projects in thermal equipment and energy efficiency in industry. The field of activity of IST research group is the numerical modelling of fluid flow and heat transfer. Particularly, it has a large experience in computational fluid dynamics CFD in complex geometries, two-phase flows and electromagnetic simulations in the presence of strong coupling between the electromagnetic and thermal fields as in the case of the microwave of high temperature materials.